|

|

R. GOVIND - M.H. YILMAZ, 2017; ICBEST 2017

Facade Failures, Seminar Article

FAÇADE FAILURES DUE TO PROJECT DESIGN DEVELOPMENT AND WORKMANSHIP

Abstract

There has been and will always be failures in construction business, like any other business. Engineers and Consultants are paying serious attention to prevent and learn from them.

There is nothing stationery against the nature forces. It is quite often in the façade industry, either designers pay less or no attention to the building movements or underestimate its interactions. In the building envelope, the impact will be so severe with devastating damages to the building and its services; resulting expensive rectifications and disruptive occupancy of the building.

Mistakes are being made during the design, fabrication and installation stages. However most of them are still caused by, misinterpreting the basic physics rules and the main principles.

Every failure tells us something, only if we listen to it correctly. We must not only criticize, punish or just fix it, but learn from them. We need to empathize to see which mistakes are repeated, which main principal is not understood by the designers and installers.

Basic design principles of joints and allowances for adequate movements start from these typical facade details. Simple verifications and design process may avoid disruptive impact on post completions.

Not only avoiding failures, but also using the information, researching and collecting data, will help us improve the Facade sector.

On this note two cooperating Facade Consultant Companies, each working in different regions and experienced in dealing with problematic issues, came together to share the experiences by presenting a detailed work, on reasons, facts, statistics, solutions, suggestions and future preventions on Facade Failures.

Keywords

Façade Failures, Curtain Wall damages, Cladding Failures, …

1. Introduction

Buildings as homes, offices, hotels or

hospitals, are man-made structures intended for human use. These are shelters

and physical divisions of the human habitat which supply comfort and safety.

Many of the definitions of Building say “a structure with a roof and wall for

people use”. Wall is something mentioned primarily and we believe it refers to

the outer walls.

Outer walls of the building, together with the windows,

glazings and claddings, are either a border or a filter between the indoor and

outdoor conditions. These are the elements that provide most of the comfort

conditions we need.

The severity of the problem, with the building envelope, may

vary from a minor performance loss to a devastating collapse, but in either case

our comfort or more critically our safety will be under threat. Therefore this

means, the purpose and functionality of this element of the building is not

succeeded.

There are and have been many problems occurred with the windows, curtain walls

and claddings (envelope) of the buildings. And mainly we have learned from them

a lot. But the technology has developed very fast. The Investments are getting

larger every decade, also the size of the buildings and complexity.

Unfortunately the speed of learning from past mistakes is not enough to keep up

following.

It is not possible to overview all mistakes and not necessary to

examine the ones that are not repeating. In this study, we will consider some of

these failures and mistakes through our 50 years old experience and daily facts

from some cases.

Many of these failures due to miscalculations or poor

engineering are studied before. Furthermore there are more complex problems such

as ‘nickel-sulfide inclusion’, which causes serious concerns on glass

applications. Here we will mainly focus on the mistakes or misses that were made

during the designs, shop drawing preparation or design development and

implementation stages including workmanship issues and construction failures.

That we believe, these could have been easily prevented with right approach and

checks in place. And we will try to find what reality lies behind these

mistakes, we will try to go to the roots and find if there is a common solution.

2. Methodology

The authors of this paper are from Turkey and India, consultants of projects mainly in Turkey, Singapore, Malaysia, Russia, India, North Africa and middle east countries. There are of course some similarities and differences of the failures. We are going to show some case studies, and some other examples. These are some mistakes that we observed in different projects. We have used examples from different projects in each single case study. So we can tell that these are common mistakes or common problems.

Failures must be sorted in types. Miscalculation and poor engineering problems, materials and supply chain problems, design problems and workmanship problems are the most important ones. We will focus on the last two.

2.1 Case Study 1

In fact the first case study is not only one case, this is one common

problem from three different actual projects of FMT Façade Consultants. The same

mistake has been done by the designers during the shopdrawing phase and also by

the technicians during the installation.

Let’s have a look at some design development stage problems;

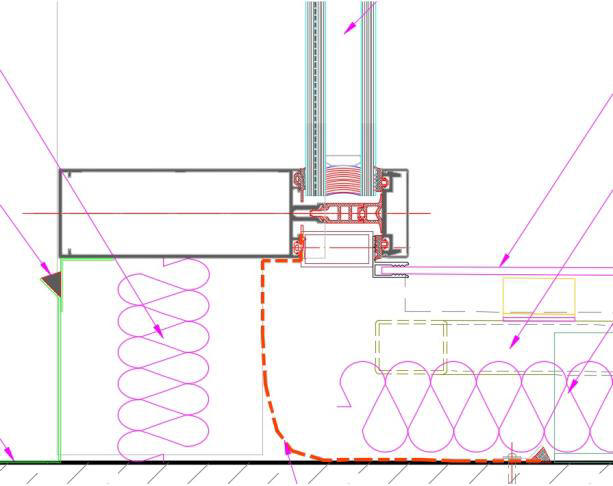

The first project is in Istanbul, erected recently (year 2014). Below

drawing was submitted by the façade contractor as the shopdrawing. The Façade of

this part of this building has been designed as “window wall”, glazed facades

are located between slabs and the slab edges are covered with metal sheet

cladding. Therefore in each floor there is a bottom end of the glazed façade.

Because of the heights of the floors and since in Turkey there is not any

developed window wall systems such as in the U.S., usually the façade specialist

are using Stick Curtain wall system elements.

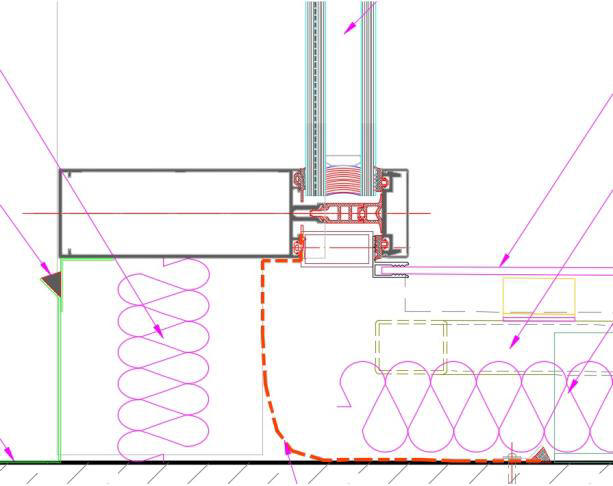

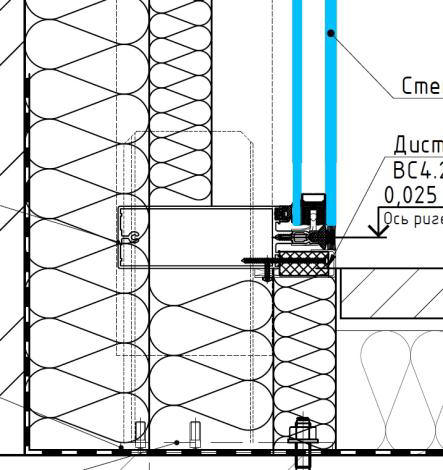

Figure 1, submitted detail of Istanbul1 Project

This is a Stick Curtain wall system, used as

window wall, and the façade contractor submitted this drawing for the bottom

connections. Façade Consultant was involved in the project after installation

started, to inspect the problems in this project.

As it can be seen, there is an insulation

membrane shown with red. And the technicians in the jobsite applied the

membranes exactly as they are in the drawings.

Figure 2, the work on the site

As shown in the above picture, technicians kept respecting the shopdrawings. And

as it can be seen in the picture, the water insulation is in front of the system

elements.

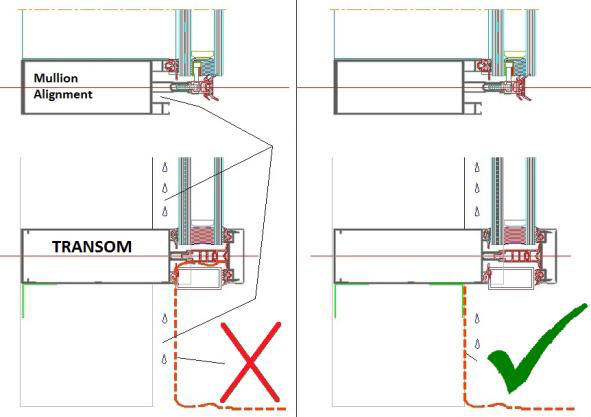

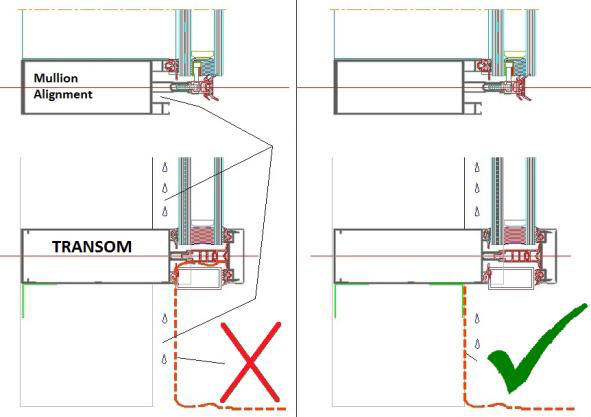

Below drawing was an explanatory warning to the

Contractor.

Figure 3, graph shows misplacement of membrane

And also

water drainage pipes were not used. The result is shown in the pictures below.

Figure 4, water leakage

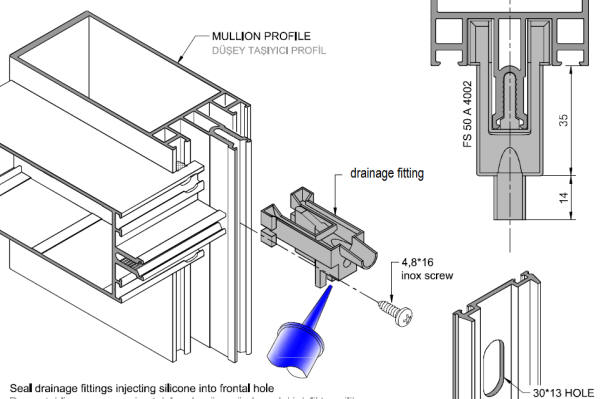

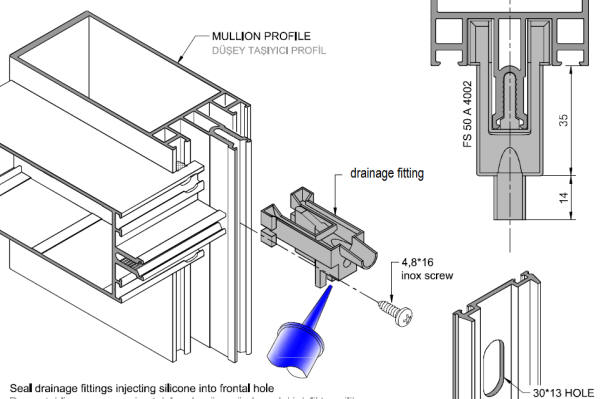

These leakages were experienced after the main contractor was warned with the

report including figure 3 above. Finally the façade specialist, used drainage

fittings (pipes) and sealed the bottom line of the system in order to direct the

water out.

Figure 5, water drainage fitting

This case shows us that neither the white collar people preparing these drawings

nor the blue collars, have any idea about the façade system, how the water

moves, how the pressure difference helps water infiltration and what

condensation is.

These are all basic

principles that can only be learned through the scientific approach. And must be

taught to all façade teams including the installation technicians.

Another design mistake with the same problem;

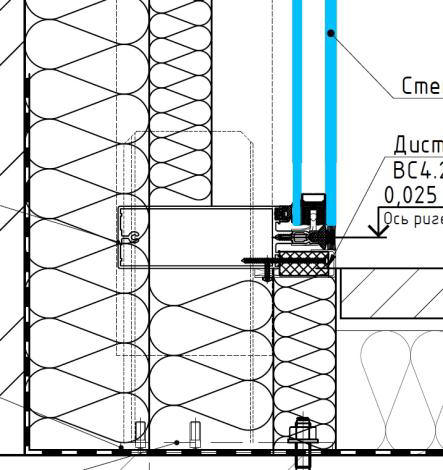

Figure 6, Submitted Detail from Moscow Project

But this case is

from another city, another Country and by another Façade specialist. The Russian

contractors did the same mistake in their shopdrawings.

Fortunately, Façade consultant was involved during the design development stage

so the contractor was warned and they corrected these details for allowing the

water drains outside.

In these two

examples the problem was caused by the shopdrawing designer, but below example

shows us even though the drawing was correct, the installation crew made the

same mistake;

Figure 7, Installation of

Istanbul2 Project

2.2 Case

study 2

Below example is from

India.

As we have mentioned, there

is nothing stationery against the nature forces. It is quite often in the facade

designs industry, either designers pay no attention to the building movements or

underestimate its interactions.

The

impact will be so severe in the building envelope with devastating damages to

the building and its services. There will be expensive rectifications and

disruptive occupancy of the building as a consequence. Some facts of similar

instances from a building investigation have been presented here.

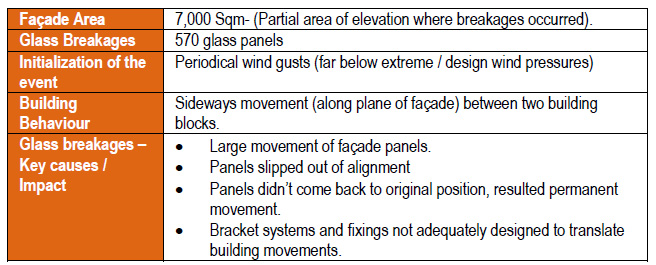

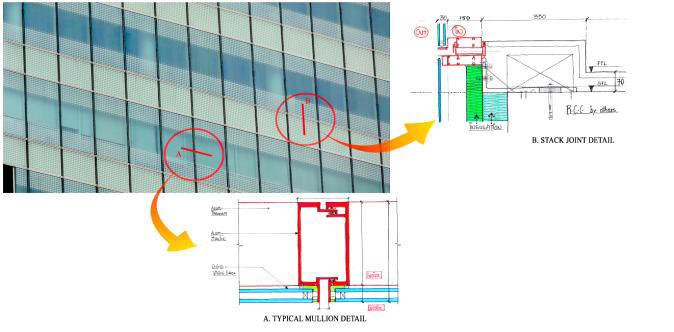

Figure 8, Building (in Mumbai) with shattered glass units

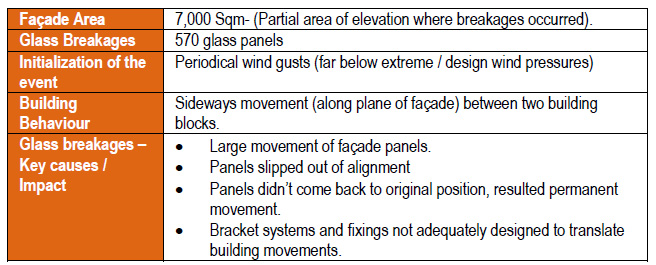

Figure 9, Quick Facts; Key figures of glass breakages of the building

Following; showing pattern of failure modes of Unitized Curtain Wall systems and

causes

Figure 10, Failure modes

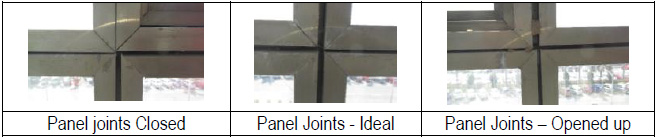

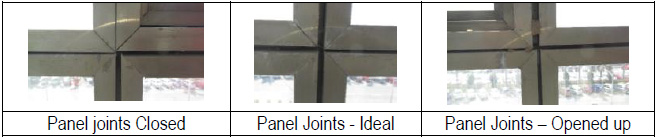

Pictures illustrate the impact

and post instance scenario of façade glazing panels behaviors. Excessive joints

movements are evident in these pictures of external and internal façades

Figure 11, External view of joints failures

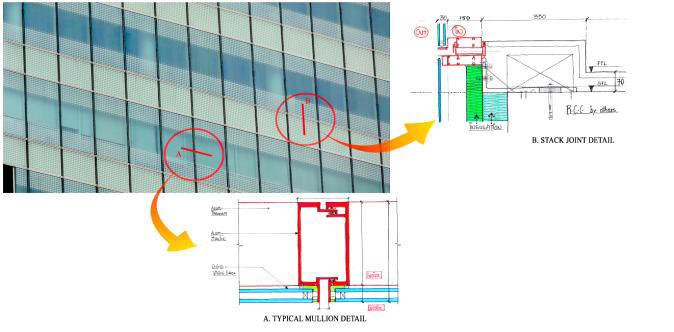

Building Facades – Movements and joint designs;

Basic design principles

of joints and allowances for adequate movements start from these typical facade

details.

Simple verifications and design process may avoid disruptive impact on post

completions.

Figure 12, Joint design illustration

2.3 Case study 3

Below there are some pictures from a very common mistake about the thermal

movement ignorance. Either the designers or the installation crew,

underestimated the thermal expansions.

These examples are from

Istanbul and Moscow.

Figure 13, Spacer Left in the expansion Joint

Figure 14, Temporary Adjustment Screw Left in the expansion Joint

Figures 15&16, Expansion not allowed with fixed bolts.

It

is clearly seen that, in these four different jobsites, the façade specialist

installation crew have no idea about the thermal expansions and thermal

expansion joints.

Therefore these cases are showing us the

importance of the scientific facts and how easily these facts are underestimated

due to the lack of knowledge and education.

3. Results and Discussion

Failures are threats to human life and safety,

moreover failures cause loss of time, money, prestige and most importantly

precious human life.

What we have seen in these case studies

could have been prevented easily if the designers or implementing team had

specific skills and experiences. On the other hand it is very obvious that,

overall skills and manpower of some building envelope industry and supply chain

are trained and already upgrading their skills as well as the adequate checks

and supervisions are completed.

For example, the system designs

of well known system house companies are tested and verified or IGU’s that are

obtained from producers are under well QAQC procedures. But when it comes to the

construction phase and the time is one of the most important issues, then the

controls and verifications are getting weaker.

System houses

design the systems and their components very well and describe it in their

manuals sufficiently, but when it comes to connect them with other structures,

mount to the building structures, both the design developers of the

construction, the crew preparing the shopdrawings, and the foremen plus workers

skip some crucial basics of physics and general rules.

Pressure

differences – pressure equalization, building movements, pressure gradients of

the facades, thermal movements are the most important examples of these rules.

It seems that those technical teams do not have enough education about the basic

physics rules. Of course we are speaking about our regions but let us not forget

that these are the fastest growing regions and the demand of buildings is still

increasing.

It is very clear that the project detail designers

and the installation crews must be educated about the building physics, they

need to know why there is a thermal expansion gap or what is water drainage.

The façade specialist companies must give importance to their inspections as

well as their internal educations. I have seen some internal random inspections

of façade specialist companies but only in few cases. Usually there is no double

check with the stage of design development – shopdrawings and installation. On

the contrary it is observed that the controls during the factory productions are

sufficient enough. Therefore the façade specialist must give the same importance

to the jobsites as well as their factories.

Another safe way of

controlling the jobsite phase must be done by the developers or main contractor

by using the façade consultants.

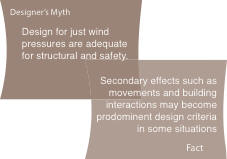

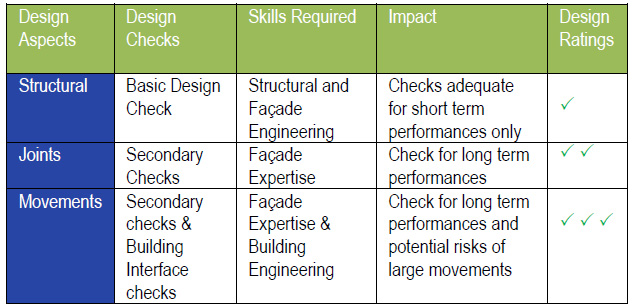

Designer’s Skills vs Practice

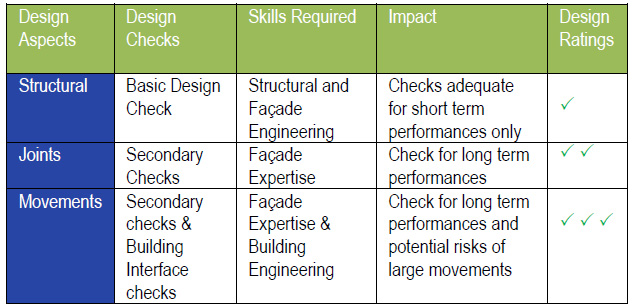

Matrix illustrates the relationship between the

designer’s skills and possible outcome of the designs.

Figure 17, Skills

Figure 18, Rating Design

Either during the designing stage or the site works, the power of nature and

materials must not be underestimated, on the contrary these must be calculated

very carefully. Even though the correct application is shown in the drawings,

the installer can underestimate and continue with his own way. This implicates

that the education of both the designers and the installers, has a very high

importance and necessity.

References

Yilmaz, H. (1999). Cephe Sistemleri ve Cephe Kaplamaları, YEM Yayınları.

TS EN ISO 13830: Curtain Wall Product Standard, 2016.

ICBEST Istanbul, 15-18 May 2017, Istanbul / Turkey

|

|